Axial Flow Compressor Solved Problems - Compressors commonly used for this application include reciprocating piston. Stage velocity triangles slip factor power input factor Stage work Pressure developed stage efficiency and surging and problems.

Solved Problem 2 In An Axial Flow Compressor Air Enters The Chegg Com

WR 2500 N.

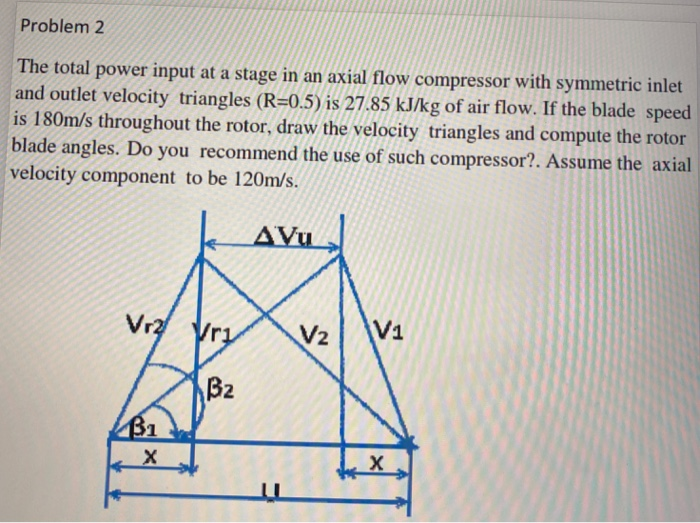

Axial flow compressor solved problems. First the axial flow. The introduction chapter quickly sets the stage for the rest of the book which is entirely focused on. Air compressors provide pressurized air to operate tool or instrument air systems.

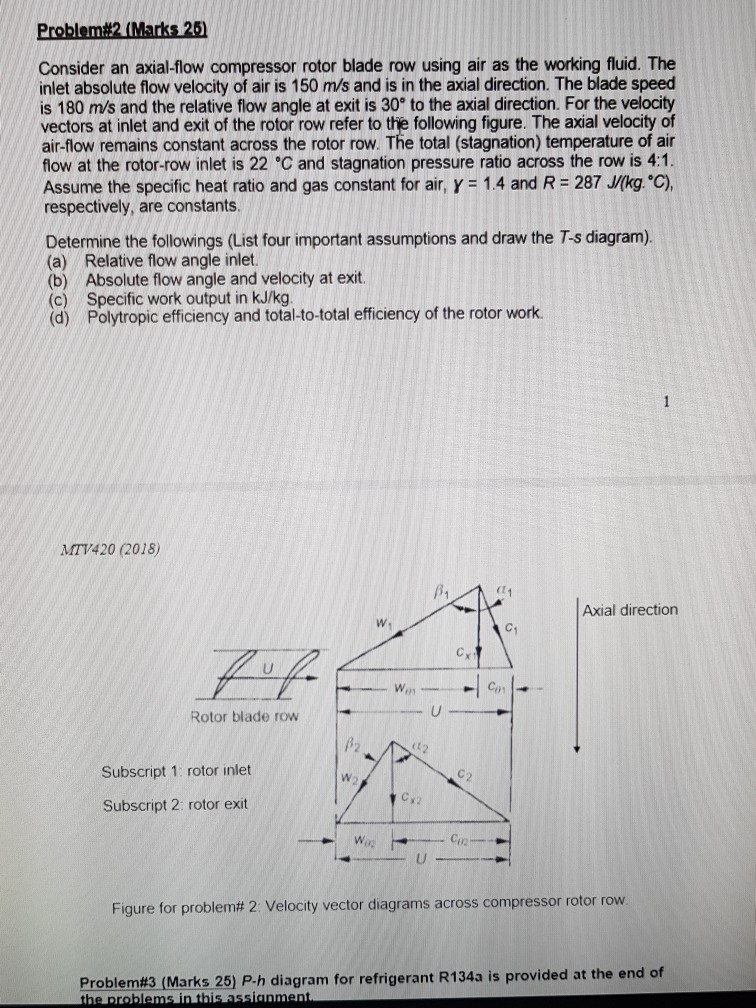

Where n is the axial flow f is shear flow x is axial coordinate and s is curvilinear coordinate along cross-section. B α 2 β 1. Problem2 In an axial flow compressor air enters the compressor at stagnation conditions of 1 bar and 290 K.

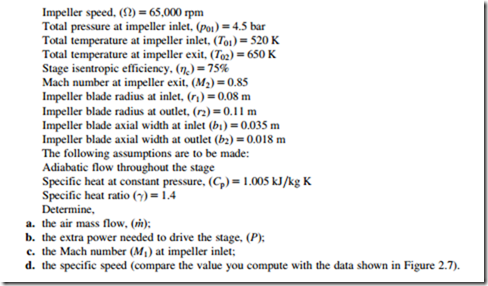

Calculation of dead volume in a piston compressor. Comparing Efficiencies of Two Axial Compressors for Bidding Solution for. For the usual case.

Analysis of a High-Performance Axial-Flow Air Compressor Solution for Problem 101 Problem 102. The compressor runs at 160rpm with average piston speed of 150 mmin. And the ratio of the axial flow velocity to the blade speed.

An axial flow compressor is originally designed with free vortex law and has degree of reaction Rx 06 at the mean with hubtip radius ratio of 06 at flow angles at the mean radius are given as α. The bearing is to carry a radial load of 2500 N and an axial or thrust load of 1500 N. This was necessary for two major reasons.

High starting power requirements. Compressor selection based on the specified conditions. Most chapters contain a few exercises at the end that are also nearly solved in the Answer to Exercises section at the end of the book.

High price as compared to the centrifugal compressor. In axial flow compressors the centrifugal effect is minimal because the radial component of velocity is suppressed and the flow is basically quasi-two-dimensional a function primarily of the axial and azimuthal coordinates z and θ. Mostly these have manufacturing problems due to their complex design.

Some or all of these compressor types may be found in any industrial facility functioning in one or more of four primary applications. These are more efficient than reciprocating compressors. The compression follows the law PV 135 C.

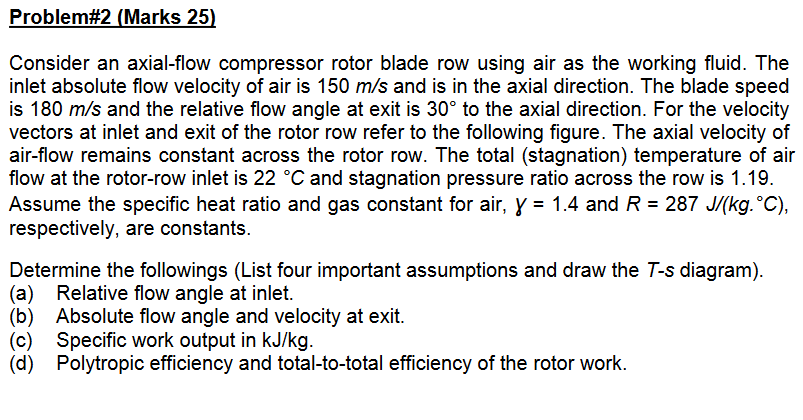

WA 1500 N. Problem2 In an axial flow compressor air enters the compressor at stagnation conditions of 1 bar and 290 K. Transcribed image text.

The Axial flow compressor in most of the advanced gas turbine is a multistage compressor consisting of 17-22 stages with an exceedingly high pressure ratio. Application of Axial flow compressor Application of Axial flow compressor- 1. Efficient in a narrow speed range.

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features Press Copyright Contact us Creators. Since the two flow angles expressed this way are nearly constant the temperature ratio becomes a function primarily of two variables the tangential Mach number MT.

C α 1 β 2 and β 1 α 2. Dynamic compressors include centrifugal and axial flow types. Expression for pressure ratio developed in a stage work done factor efficiencies and stalling.

Determination of flow rate and consumed power of compressor equipment. Power P 150KW. An axial-flow compressor is a high-speed and very large-volume compressor that works as you may have already guessed by the flow entering the compressor in the axial direction.

Design of axial compressor which includes 1D 2D. Overall Compressor Efficiency for a Four-Stage Compressor Solution for Problem 102 Problem 103. Axial flow compressor has a heavyweight.

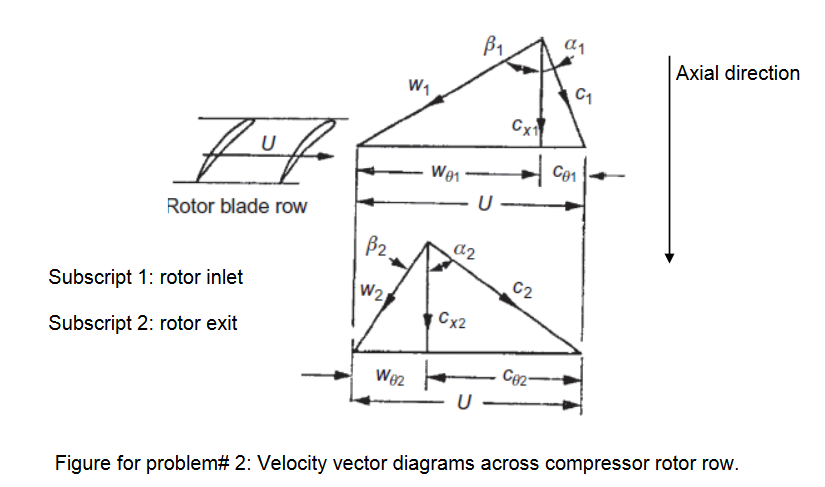

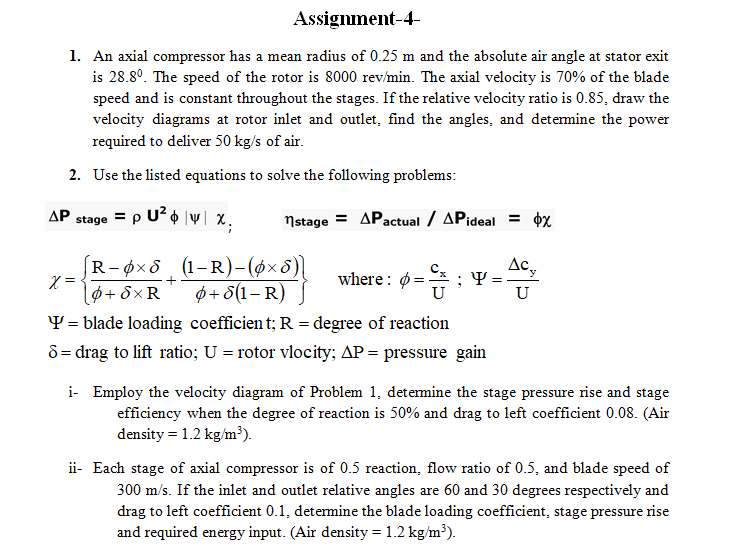

The rotational speed is 5500 rpm and stagnation temperature rise is 22 K. They are a form of dynamic compressor that contains rotary and stationary components through which the air flows and then becomes compressed. 0 Calculate the relative and absolute flow angles at the hub and tip both at the inlet and the exit of the rotor.

α 1 exit angle from stator β 1 inlet angle to rotor α 2 inlet angle to stator and β 2 outlet angle from rotor. High power demands on the starting power. Assuming light shock load determine the rating life of the bearing.

An axial flow compressor is to be designed to raise the temperature of the air entering the combustion chamber. The condition to have a 50 degree of reaction is. Piston speed 2lN 150m min.

Here we can substitute n sigma t. SOLUTIONS TO FIELD PROBLEMS OF A GAS TURBINE-AXIAL FLOW CHEMICAL PROCESS COMPRESSOR TRAIN BASED ON COMPUTER SIMULATION OF THE PROCESS 79 Axial Compressor Instrumentation The axial flow compressor is fully instrumented so that detail section data can be obtained. Cost is very high.

A α 1 β 2. A single row angular contact ball bearing number 310 is used for an axial flow compressor. D α 1 α 2 and B 1 β 2.

Work done Degree of Reaction Losses and Efficiency. Axial flow Compressor 1 - YouTube. 10 Hours TEXT BOOKS.

Modification and te st resul ts of the previously. It is not uncommon to have pressure ratios in industrial gas turbines in the 17 to 201 range with some units having pressure ratios in the 301 range. Axial-Flow Pumps Fans and Compressors Review of Key Concepts Problem 101.

Noise problem in Axial Compressors and Fans BR 1 Solved Examples and Tutorial Problems 2 Tute 3 Axial flow turbines 13 Introduction BR 1 Turbine stage AMP 3 Lec 1 Tute Turbine Blade 2-D cascade analysis Work Done Degree of Reaction Losses and Efficiency Flow Passage Exit flow conditions Multi-staging and Multi-spooling of Turbine AMP 1. Some of the experience. The Axial-Flow Compressor book by Aungier has 13 chapters spread over 348 pages.

Air enters with an absolute velocity of 145 ms axially into the first stage of the compressor and axial velocity remains constant through the stage. Determination of the number of compression stages in a compressor and pressure values at each stage. Positive displacement compressors include reciprocating piston types of various.

Noise Problem in Axial Compressors and Fans. Blade and Axial Flow Passages Exit Flow Matching with Nozzle. Disadvantages of Axial Flow Compressor.

Introduction to Turbines Aerothermodynamics. Advantages Disadvantages of Axial Flow Compressor Disadvantages- 1. Where M1 is the flow Mach number upstream and MT is the tangential Mach number of the blade motion.

Thus c r 0 and w r 0 and c czθ and w wzθ. A single stage double acting air compressor of 150KW power takes air in at 16 bar delivers at 6 bar. Good efficiency over narrow rotational speed range.

Turbine Blade 2D Cascade Analysis. The average chapter length is thus 27 pages. In an axial flow compressor.

Determine the size of the cylinder.

Axial Flow Compressor 1 Youtube

Solved Problem 2 Marks 201 Consider An Axial Flow Chegg Com

Axial Flow Compressor Pdf Pdf

Solved Problem 2 Marks 25 Consider An Axial Flow Chegg Com

Axial Flow Compressor 5 Youtube

Solved Problem 2 Marks 25 Consider An Axial Flow Chegg Com

Beautiful Flower Axial Flow Compressor Problems

Beautiful Flower Axial Flow Compressor Problems

Solved Problem 8 24 Aircraft Propulsion Farokhi An Axial Flow Compressor Stage Is Downstream Of An Igv That Turns The Flow 15 In The Direction Of T Course Hero

Solved Problem 8 24 Aircraft Propulsion Farokhi An Axial Flow Compressor Stage Is Downstream Of An Igv That Turns The Flow 15 In The Direction Of T Course Hero

Solved Assignment 4 1 An Axial Compressor Has A Mean Chegg Com

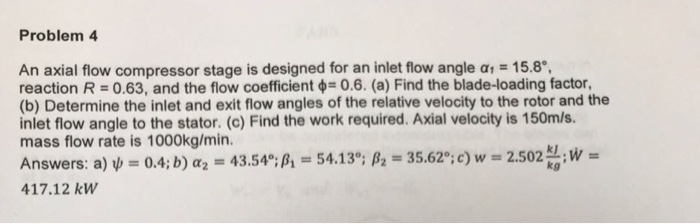

Solved Problem 4 An Axial Flow Compressor Stage Is Designed Chegg Com

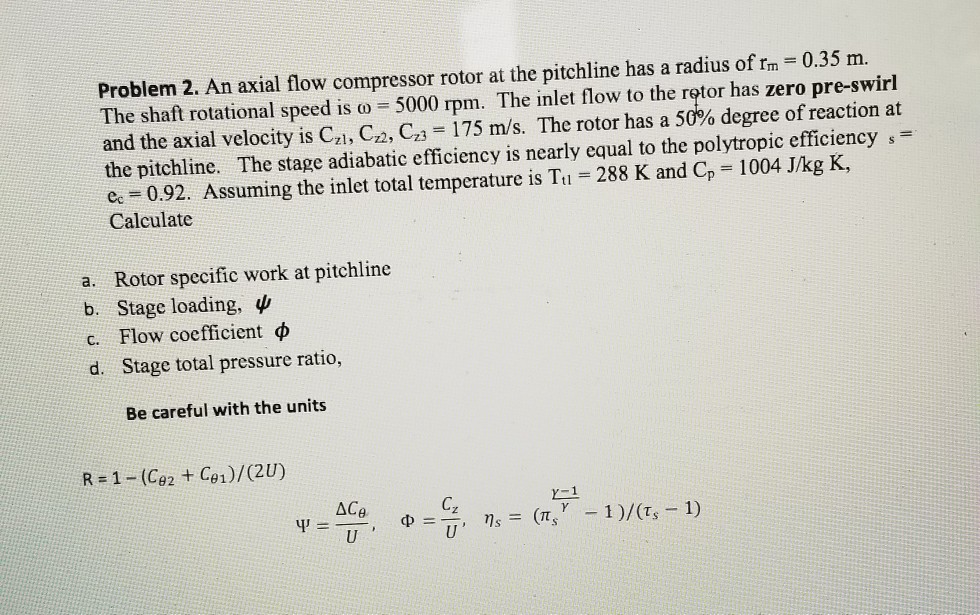

Solved Problem 2 An Axial Flow Compressor Rotor At The Chegg Com

Solved Example 6 1 An Axial Flow Compressor Stage Is Chegg Com