Axial Flow Compressor Nptel - Units over 5MW use axial fl ow compressors. Introduction to TurbomachineriesAxial flow compressors and Fans.

Mod 01 Lec 02 Axial Flow Compressors And Fans Introduction To Compressor Aerothermodynamics Youtube

3 The pressure ratio of 81 or even higher can be achieved using a multi-stage axial flow compressor.

Axial flow compressor nptel. Turbomachinery Aerodynamics by Prof. SubjectId Discipline Name Subject Name Coordinators Type Institute Content. A M Pradeep Department of Aerospace Engineering IIT Bombay.

Ejector and variable area nozzles interaction of nozzle flow with adjacent surfaces Thrust reversal. A full course in Aerodynamics. Losses and Blade performance estimation.

Effect of operating variables on performance. Compressor is a device which is used to increase the pressure of air from low pressure to high pressure by using some external energy For filling the air in tube of vehicles In automobile service station to clean vehicles. Axial flow compressors produce a continuous flow of compressed gas and have the benefits of high efficiency and large mass flow rate particularly in relation to their size and cross-section.

In the stator the kinetic energy transferred. In an axial Discharge compressor flow moves in an axial direction from left to right in this diagram rather than in a circular direction as in centrifugal compressors. The course contains the analysis of vapour power cycle ie.

On the other surge represents a point at which the compressor will. FreeVideoLectures aim to help millions of students across the world acquire knowledge gain good grades get jobs. Principle of Operation of Axial Flow Turbines.

It is a detrimental phenomenon as it will make the compressor to vibrate. A M Pradeep Prof. Aero-Thermodynamics of flow through an Axial flow Compressor stage.

Introduction to Compressor Aerothermodynamics. Ravi Kumar Department of Mechanical Industrial Engineering Indian Institute of Technology Roorkee. Performance Parameters of Axial Flow Turbine.

Introduction to Fluid Machines and Compressible Flow by Prof. Basic operation of axial compressors Axial flow compressors usually consists of a series of stages. Mod-01 Lec-25 Axial Flow Compressor Part II.

Losses in axial flow compressor stage. Advantages of axial flow compressor are as follows 1 It has higher efficiency than a centrifugal compressor. Constant Nozzle Angle Designs.

Lecture Series on Steam and Gas Power Systems by Prof. Turbomachinery Aerodynamics Free Aerospace Engineering Online Course On NPTEL By IIT Bombay Bhaskar Roy A M Pradeep Intro. For more details on NPTEL visit httpnpteliitmacin.

Without a doubt Surge might create a dead-end for natural gas compression. The cascade effect is a primary consideration Figure 1. The aerodynamic principles are applied to the compressor design to increase axial compressor effi ciency.

The energy level of the fluid increases as it flows through the compressor due action of the rotor blades which exert a torque on the fluid. Effect of pressure velocity and temperature changes of air entering compressor. Introduction An axial compressor is a machine that can continuously pressurize gases.

This kinetic energy of the fluid is converted into pressure energy by diffuser action. 2 It is more suitable for multi staging increase in pressure with negligible losses. Mod-01 Lec-02 Axial Flow Compressors and Fans.

A axial b centrifugal and c mixed fl ow compressors. Flow exits an axial rotor left in an axial direction while flow from a centrifugal impeller right exits radially. In vehicle to operate air brakes.

Centrifugal Pumps The pumps employing centrifugal effects for increasing fluid pressure have been in use for more than a centuryThe centrifugal pump by its principle is converse of the Francis turbine. The axial compressor blades are treated as lifting surfaces like aircraft wings or propeller blades. For spray painting in paint industries.

In the axial flow compressor fluid is imparted with kinetic energy from the rotor. Basic Blade Profile Design Considerations. They do however require several rows of.

The stationary blades slow the fluid converting the circumferential component of flow into. Mod-01 Lec-01 Introduction to Turbo machines Syllabus References and Schedules. SomDepartment of Mechanical EngineeringIIT KharagpurFor more details on NPTEL visit httpnptelacin.

Matching of Compressor and Turbine. The working fluid is initially accelerated by the rotor blades and then decelerated in the stator passages. This Course provides a simple understanding of the steam and gas power systems.

Like turbines pumps are classified according to the main direction of fluid path through them like i radial flow or centrifugal ii axial flow and iii mixed flow types. Turbine Blade Cooling Methods. Introduction - A simple two dimensional analytical model - 2-D Losses in axial flow compressor stage - Profile Loss and Blade performance estimation - 3-D flows in Blade passages - Secondary flows Tip leakage flow Scrubbing - Simple three dimensional flow analysis - Full Radial Equilibrium.

Each stage comprises of a row of rotor blades followed by a row of stator blades. Shock swallowing by area variation Real flow in nozzles and nozzle efficiency losses in nozzles. 4 It can handle a large amount of air.

Aerothermodynamics of Aircraft Engine Components. Based on direction of flow through the impeller or vanes or blades with reference to the axis of shaft rotation a Axial flow Axial pump compressor or turbine b Mixed flow Mixed flow pump Francis turbine c Radial flow Centrifugal pump or compressor d Tangential flow Pelton water turbine 4. Tip leakage flow and scrubbing.

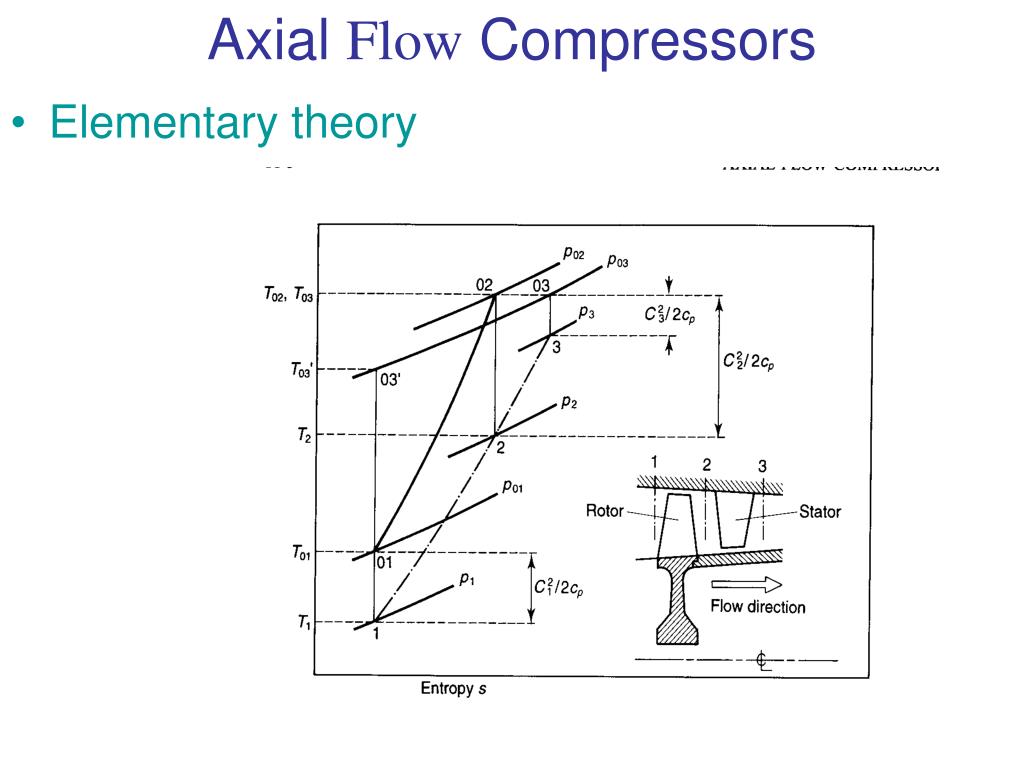

Introduction to Aerospace Propulsion. Rankine cycle steam generators and their accessories Performance of Boilers and combustion of fuel high pressure boilers flow through steam and gas nozzles different type of steam turbines for power. Two-dimensional pitch line design and analysis h-s diagram degree of reaction the effect of Mach number performance and efficiency three-dimensional flow tip clearance losses compressor performance and illustrative examples.

Compressor surge is the process of formation of the reversible flow of gas through the compressor axial or centrifugal type. Work Done and Pressure Rise. Limitations of Radial Flow Turbines.

It is a rotating air foil-based compressor in which the gas or working fluid principally flows parallel to the axis of rotation. The process occurs over several stages. Axial Centrifugal p Figure 3.

The energy analysis is considered for one stage of the compressor. Lecture 4 - 2D losses in Axial flow Compressor Stage Lecture 5 - Tutorial 1 Lecture 6 - 3D Flows in Blade Passages Secondary Flows Tip leakage Flow Scrubbling Lecture 7 - Three Dimensional Flow Analysis Lecture 8 - Classical Blade Design Laws Lecture 9 - Three Dimensional Flow Analysis in Axial Flow Compressor Lecture 10 - Tutorial 2. Axial flow compressor.

An axial fl ow compressor is one in which the fl ow enters the compressor in an axial direction parallel with the axis of rotation and exits from the gas turbine also in an axial direction. Axial flow compressors and Fans 17 Introduction BR 1 A simple two dimensional analytical model AMP 1 2-D Losses in axial flow compressor stage AMP 1 Lec 1 Tute NPTEL httpnpteliitmacin Aerospace Engineering Pre-requisites.

Ppt Axial Flow Compressors Powerpoint Presentation Free Download Id 956113

Nptel Online Iit Kanpur

Mod 01 Lec 24 Axial Flow Compressor Part I Youtube

Lec 33 Examples Of Axial Flow Compressor Youtube

Nptel Online Iit Kanpur

Nptel Online Iit Kanpur

Nptel Online Iit Kanpur

Nptel Online Iit Kanpur

Nptel Online Iit Kanpur

Nptel Online Iit Kanpur

Nptel Online Iit Kanpur

Axial Compressor Working Principle And Applications

Mod 01 Lec 02 Axial Flow Compressors And Fans Introduction To Compressor Aerothermodynamics Youtube

Nptel Mechanical Engineering Fluid Machinery