Bag Filter Design Handbook - Since the product specified here is used under various operating conditions its compatibility with specific. 8000cfm air required for dust control Kice VR96-10 Filter offers 4343ft² of.

Pdf Cfd Model Validation Of A Bag Filter For Air Filtration In A Milling Plant

Design Considerations Interstitial Velocity Upward velocity of airparticulate between filters inside baghouse Measured in fpm feet per minute Determined by dividing airflow cfm by cross sectional area of filter housing less bag area Not to be confused with can velocity EXAMPLE.

Bag filter design handbook. Collected dust cakes onto the baghouse. These filters are commonly called baghouses. Design hints for single-supply filter designs.

Fabric filters collect particles with sizes ranging from submicron to several hundred. Bility is called bag reach and is the maximum number of rows from the nearest walkway. Overall pressure drop of a multi-compartment baghouse Pulse-Jet Baghouse In a pulse-jet baghouse felted filters are typically used as bag material although woven fabrics can also be used.

Fabric Filter Design Variables 20-395 3-5 Figure 3-2. Essentially all pleated filters are shorter than pulse jet bags. F gas flow at 25 C given in m3min c concentration of dust given in gm3 φ average diameter of the particle in μm For example con F700 m3min c 40 gm3 φ 50 μm.

Our engineering team has 30 years of experience in surveying the output and needs of various plants and will study yours to find an appropriate solution to reach your desired emissions reductions. There is no single value for bag reach but typical units have a value of 3 or 4. Volume occupied by the filter m3.

The most desirable media size depends on the suspended solids characteristics as well as the effluent quality requirements and the specific filter design. If you know the diameter of the bag multiply this diameter by 314 to get the circumference. Bag Filter MODE Series.

Air to cloth ratio filtration velocity intersticial velocity and can velocity. The design should include an extra compartment to allow for reserve capacity and inspection and maintenance of. 19 kg Makes the work of tightening easy.

Hello Friends I have to design a bag filter to control particulate emission from a coal pulverizer. In general rapid sand filters use sand with an effective size of 035-060 mm 0014-0024 in and a. Compared to a bolt tightening system with many places between 4 and 6 that need to be tightened this.

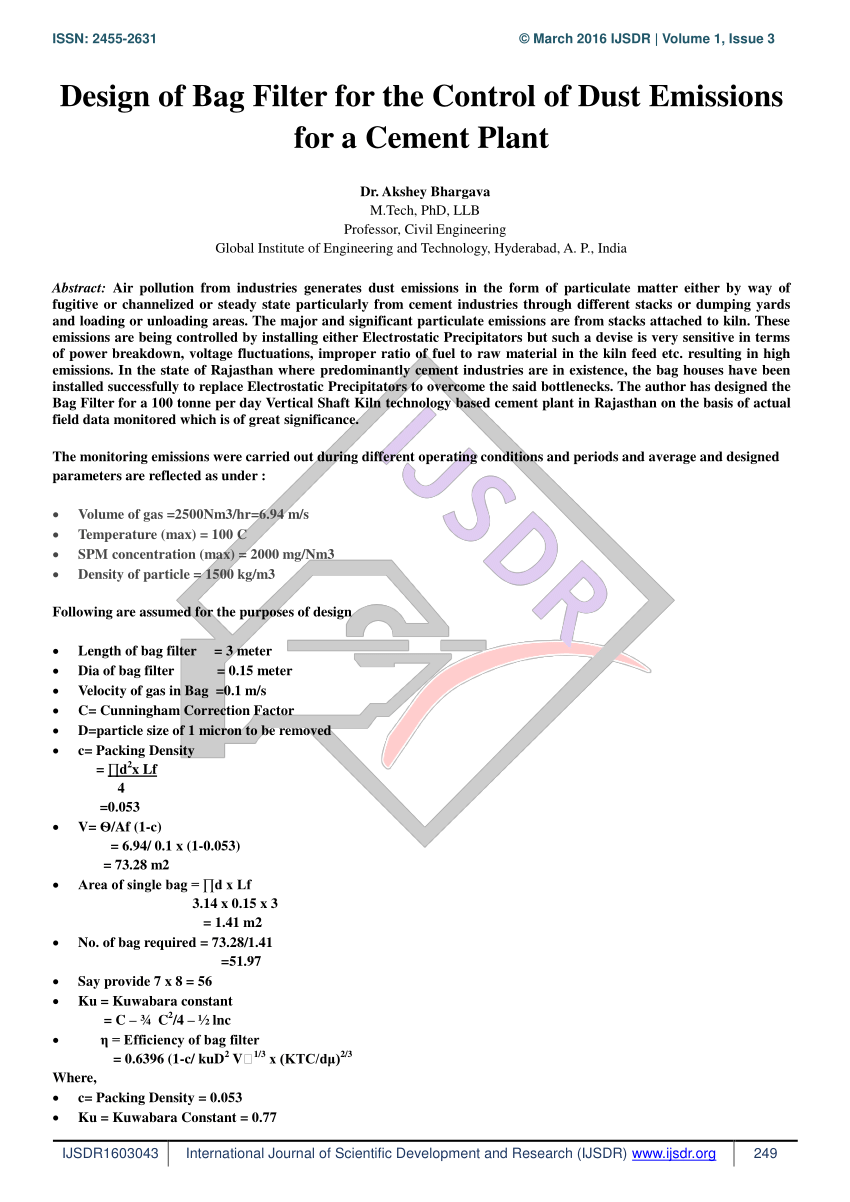

Following are assumed for the purposes of design Length of bag filter 3 meter Dia of bag filter 015 meter Velocity of gas in Bag 01 ms C Cunningham Correction Factor Dparticle size of 1 micron to be removed c Packing Density d2x Lf 4 0053 V ѲAf 1-c 694 01 x 1-0053 7328 m2. Pleated bag 223 Pleated bag The filter media is usually a felted material composed of cellulose polypropylene or other flex-resistant material. Depending on the duration of the pulse that is required high pressure 3 7 bar over-pressure intermediate pressure 1 2 bar over-pressure or low pressure 05 07 bar.

As 1 RC s 1 RC 1 1 sRC. Dirty air is either pushed or pulled through the baghouse filter bag by a fan. R C VIN VOUT Figure 16 2.

Bag Filter Vessels. 162 Fundamentals of Low-Pass Filters The most simple low-pass filter is the passive RC low-pass network shown in Figure 16 2. Bag filter offers excellent safety performance and ease of maintenance.

The bags are typically long cylindrical tubes. During cleaning dust that has accumulated on the bags is removed from the fabric surface and deposited in a hopper for subsequent disposal. PULSE JET BAG FILTER DESIGN Where.

Dust is collected inside or outside the baghouse filter depending on the airflow design. The hydrophilic polyethersulfone membrane resists a wide variety of chemicals.

They can be supported at the top and bottom or have a frame inside. A filter bag calculation can also be made because filter bags are round. How to size a bag filter system.

Handbook o f Fabric Filter Technology. Trevor Sparks George Chase in Filters and Filtration Handbook Sixth Edition 2016. When designing a dust collector using bag filters the following design sizing criteria must be studied.

32 lighter than the current model Weight. Think back to high school math and the circumference of a circle Therefore the circumference of the bags diameter of the bag x 314 multiplied by the length of the bag will. The filtering surface SF given in m2 is estimated using the following expression.

The design of Bag Filter in the present paper would demonstrate efficiency to the extent of 998 perce nt and as such would be able. Some pleated filters have simple. To determine the appropriate filter size we must study the air-.

Design of a baghouse or fabric filter. The unique feature of a pleated filter is the design of the filter element. Since there are no openings in the fabric material there is no ini-tial cake buildup period.

Take the CFM of the system and divide it by the total filter cloth area to get your air to cloth ratio. The compartment design should allow for proper cleaning of bags. Evadur achieves very high fl ow rates while maintaining a very low differential pressure.

Filter bags for liquids are effective in removing particulate contaminants in the processing of a wide variety of materials. Pleat design and rugged construction for superior retention and fi lter life. Collector by calculating the total filter area of each filter bag diameter x 314 x length 144 for number of inches in a square foot filter cloth area and then multiply that figure by the total number of bags in the collector.

What Does a. 11 Filters and Signals. This Application Note is intended to serve as a very basic in-troduction to some of the fundamental concepts and terms associated with filters.

13 kg Current model. It will not turn a novice into a filter de-signer but it can serve as a starting point for those wishing to learn more about filter design. 491 Bag filters 4911 Bag filters.

On-line cleaning a few bags at a time while the rest of the filter bags continue filtration and is most suitable for outside-in filter systems. First-Order Passive RC Low-Pass Its transfer function is. Required filtration area calculation filter sizing Bag filter sizing.

The filter is operated cyclically alternating between relatively long periods of filtering and short periods of cleaning.

Bag Filter Design Pdf Manufactured Goods Gases

Best Bag Filter Documents Scribd

2

Bag Filters For Dust Design Materials Filter Size Calculation

Pdf Design Of Bag Filter For The Control Of Dust Emissions For A Cement Plant

2

Bag Filter Design Calculations Pdf Equipment Nature

2

2

2

Bag Filter Design Calculations Pdf Equipment Nature

2

Bag Filter Design Software Home Facebook

Baghouse Wikiwand